Get In Touch

Contact Info

- 6420 Guion Road, Indianapolis, IN 46268

- 317 755-1700

- ecogolf@aol.com

- Monday-Friday 9:00 AM - 5:00 PM

DIRECT TO FILM (DTF)

- Home

- DIRECT TO FILM (DTF)

DTF and Transfer Printing: Ultimate Guide to Superior Custom Printing

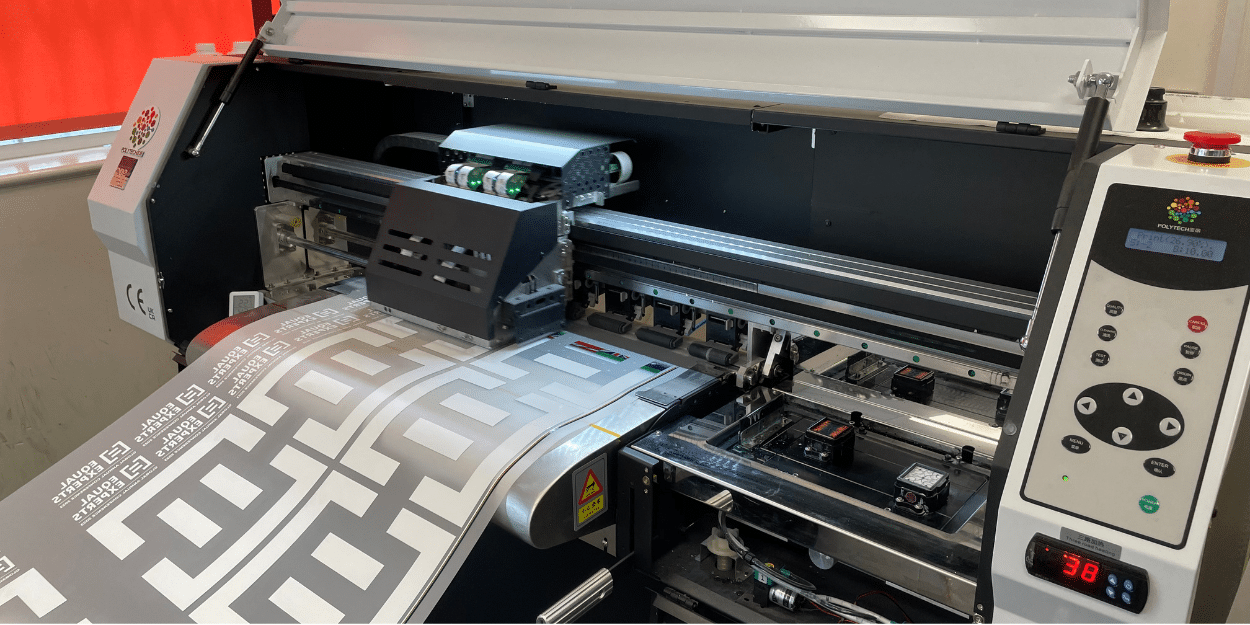

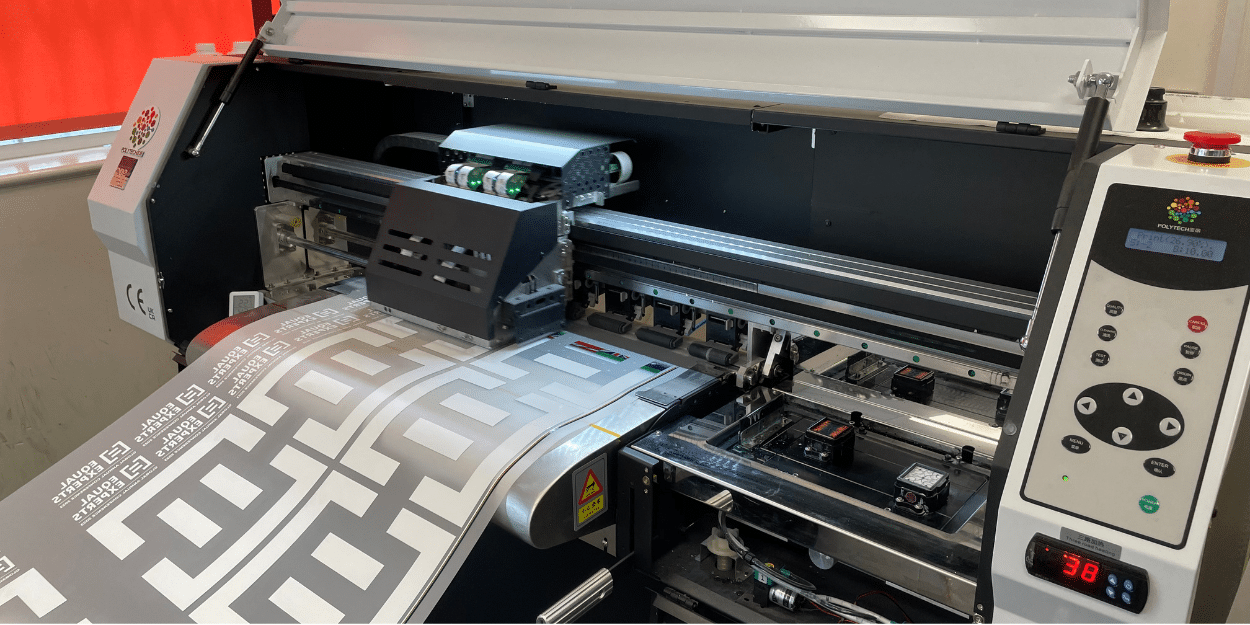

In recent years, Direct to Film (DTF printing) and transfer printing have transformed the world of custom garment branding, enabling faster production and high-quality results across a wide range of materials. This comprehensive guide explores the methods, advantages, and applications of DTF and transfer printing — helping you understand when these techniques are the right choice for your personalised workwear.

Introduction to DTF and Transfer Printing

Direct to Film (DTF) and transfer printing are transforming the custom garment industry by offering flexible, high-quality printing solutions for apparel and promotional wear. DTF printing involves applying designs to a film before heat pressing onto the fabric, while transfer printing uses specially prepared transfer media to achieve vibrant, durable results across multiple materials.

What is DTF Printing?

DTF printing is a process where designs are printed onto a special film and then transferred onto fabric using heat and pressure. It delivers vivid colours, excellent durability, and works on a wide range of materials — making it ideal for personalised clothing and branded workwear.

Basics of Transfer Printing

Transfer printing involves printing artwork onto transfer paper which is then applied to garments using heat and pressure. This method produces sharp, high-quality prints and is highly versatile across different garment types.

Advantages of DTF Printing

High Durability

DTF prints are built to last through repeated washes and daily wear, making them ideal for custom apparel and workwear that demands resilience.

Works on Multiple Materials

From cotton and polyester to blends and leather, DTF printing offers unmatched versatility across various garment types.

Cost-Effective for Small Batches

Minimal setup and fast turnaround make DTF perfect for small runs, custom orders, and on-demand production.

Vibrant & Detailed Prints

DTF produces bold colours and high-resolution details, even on dark fabrics, ensuring designs truly stand out.

Advantages of Transfer Printing

Vivid Colour Options

Transfer printing delivers bold, eye-catching colours, ideal for logos and intricate artwork.

Suitable for Various Materials

Works across textiles, plastics, metals, ceramics, and more — making it highly versatile.

Ideal for Small Runs

Minimal preparation makes transfer printing perfect for short production runs or limited editions.

High Precision & Accuracy

Captures fine details and sharp lines, producing crisp and professional results.

How DTF Printing Works

DTF printing uses specialized inks, PET film, hot-melt powder, and a heat press to transfer high-quality designs onto garments. When heat and pressure are applied, the adhesive bonds the design securely to the material.

1. Print Design

Create the design on PET film using a specialized DTF printer.

2. Apply Powder

Coat the printed film with hot-melt powder to enhance adhesion.

3. Heat Press

Apply heat and pressure to transfer the design onto the garment.

Best Practices

We ensure even powder coating and precise heat application for optimal results. Every design is tested before full production to guarantee clarity, durability, and professional-quality finishes — even for intricate details.

DTF vs. Transfer Printing

DTF Printing

Key Differences in Application

Best suited for textiles and garments that undergo frequent washing. Works well with stretch fabrics like activewear and hoodies, delivering durability and flexibility.

Cost & Time Efficiency

Minimal setup and fast curing make DTF ideal for short runs and custom orders with quick turnaround requirements.

Transfer Printing

Application Versatility

Suitable for textiles as well as hard surfaces including plastics, metals, glass, and ceramics.

Material Compatibility

Works effectively on polyester, leather, and blended fabrics, offering flexibility across various industries.

Materials Compatibility Overview

DTF Printing

Primarily used for cotton, polyester, and blended textiles. Can also be applied to select treated plastics and metals.

Transfer Printing

Extremely versatile — compatible with fabrics, leather, metals, glass, ceramics, and more.